Types of welding used in automobile industryWhen we speak of welding repairs, we refer to the fusion of metals to rectify a problem. MIG welding is most generally utilised in automotive repair as it is capable of supplying a powerful, sturdy weld that when done appropriately is able to withstand huge forces, delivering the level of versatility and strength that is needed for such applications. MIG welding is also typically employed in plumbing, construction, robotics and the maritime industry and is usually regarded as an improvement more than the more archaic techniques.

The ferritic type contains anyplace from ten to twenty % chromium and are mainly free of charge of nickel. Other materials employed contain titanium and niobium, which are good supplies for welding. They are not hardened by heat treating and only slightly hardened by cold-working. They are generally stronger than other varieties and have very good formability and ductility. They are known for becoming susceptible to brittle fractures at reduce temperatures. They are magnetic and have a high level of resistance to oxidation and corrosion. This kind is typically identified in hot water tanks and automotive exhaust systems.

Yet another point to contemplate is the power and portability available. If the automatic welding machine is purchased from Huizhou Shengyang Industrial Co. Ltd for use in a retailer, it may possibly not be quite transportable and will have significant access to power at all times. On the other hand, high overall performance on-web site repairs need a package that can handle different kinds and sizes of metal efficiently and at the very same time be straightforward to transport.

Automotive Castingstypes of welding in automotive industry

types of welding used in automobile industryWelding is the principal process in any manufacturing unit, construction site and automobile industry to transform metal pieces into merchandise, devices or machinery. Once you have selected the acceptable automotive service equipment, you’ll still want to practice on scraps just before operating on the final piece for the very best outcomes. This is especially accurate for aluminum and other delicate components. Also, never be afraid to watch the gauges and flow meters on the provide lines as properly as on the machine itself. In the finish, you are going to find mig welders swift and affordable whilst nonetheless carrying out a high quality job.

Ultrasonic welding was mostly utilized for fusing plastic supplies. These days it is also employed to join dissimilar metals such as copper, aluminum and brass in various bonding applications. It is generally used in harness manufacturing, as it provides reduced resistance. It is also utilized for bonding wire to terminals. These are significantly expensive and slower than other wire termination technologies. These can not be utilised with soft plating like Tin. As this welding method is very flexible, these are also deployed in the automotive market- welding multiple wires to a single frequent point inside the chassis.

Getting a properly-established name in the market, Everlast Welders has been supplying the greatest quality welders and plasma cutters that will certainly hold fulfill your requirement. In order to lure a lot more and far more buyers and to make them conscious of the latest strategies of innovative welders and plasma cutters, various kinds of campaigns are also run although eye-catching discounts are supplied to consumers.

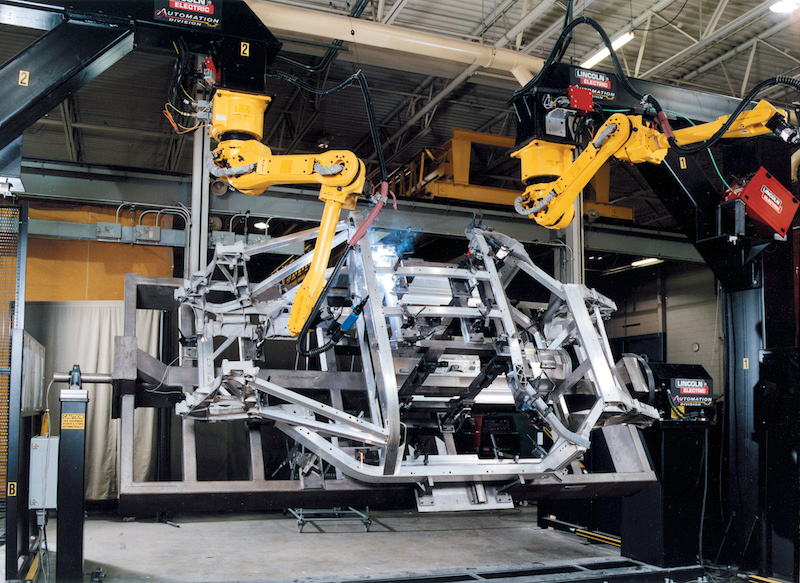

Completely Automatic Spot Welding Method For Application In Automotive

types of welding in automotive industryRust and cracks in auto panels can be simple to repair, but men and women frequently skip these repairs. The non destructive ultrasonic testing of spot welds has been applied in the automotive business for several years. Although the welds in these factories are made by controlled robots, their inspection is still getting completed manually and for a limited number of welds. When a defective weld is found it normally implies throwing away a massive quantity of material already welded. There is a want for an automated system with which to check at least 70% of the welds created and the welding parameters in one hundred% of the robots in the weld cells, and which can be totally integrated inside the operating cycles currently in spot. The technique demands to be quickly adequate to be integrated in this environment and robust so it does not force stoppages into the line.

The range of applications of the machine tools in automotive industry continues to increase exponentially. This has been enhanced by development of computer numeric controlled machines, which are in a position to transform style to completed product in a extremely brief time frame. High-speed machining methods have also enabled greater precision to be accomplished.

Using lasers in automotive production aids to drive down maintenance expenses. For instance, just one laser welding head can execute all of the welds that would have essential ten welding guns making use of traditional approaches. Not only is there much less equipment to be concerned about maintaining operating efficiently, by replacing classic welding gun with 1 laser welding head it aids to cut down on the facility’s CO2 emissions, generating it less difficult to meet international CO2 emission requirements.

Steering Toward Aluminum Trends In The Automotive Industry types of welding used in automobile industry

types of welding in automotive industryRobotic welding is utilized when an business wants to animate their welding method. ABB was the initial leading manufacturer that has installed the first paint robot in 1969 and initial microprocessor controlled electric robot in 1974. It has also provided facilities for investigation, manufacturing and development in Czech Republic, Sweden, Norway, Mexico, Japan, China and USA. ABB also supplies robot goods, services and systems worldwide. It has more than 4600 personnel in 53 countries about the planet. The crucial marketers of the ABB consist of automotive, plastics, metal fabrication, meals beverages, electronics, machine tools and beverage industries. ABB works to enhance the productivity, worker security and solution quality of the companies.

Each construction business, mining market, forestry associated trade and manufacturing sector would necessarily involve welding repairs at some stage or other. It could also be an automobile repair shop or a sophisticated machinery-manufacturing factory needing welding solutions. The point is, welding repairs are needed at different stages of all trades involving heavy equipment.

The most widespread sort is named the UBC Loose. This kind of aluminum consists of fundamentally cans utilized for colas, beer, or any other beverage. Soon after shredding them, they might be utilized in a number of methods specifically in an industrial-associated organization. We also have the Auto Wheels or Auto Transmission scraps. They are located and collected from automotive industry, hence the name. Specific components could call for disassembling ahead of they can be re-bought. One particular of the most common scrap aluminum sorts is the Cable Scrap. This type has practically a single of the greatest values in the industry. Another kind which has also an advantage in terms of value is the Remelt Aluminum. Metal workers can make use of this kind conveniently.