3D Printing In The Worldwide Automotive Market Industry

Advantages of 3d printing in automotive industryThis write-up will discuss why 3D Printing has had such a massive effect on the automotive industry and how it can be implemented to enhance functionality whilst lowering lead instances and expense. As per MRFR analysis, the worldwide 3D printing in automotive marketplace is probably to grow at a CAGR of 26.two% during the forecast period, exactly where the industry value is expected to attain USD two,512.three million by 2023. Over the years, it has been analyzed that the automotive market has come up with many technological advancements which has decreased the manufacturing and production expense as well as low upkeep cost have boosted up the demand.

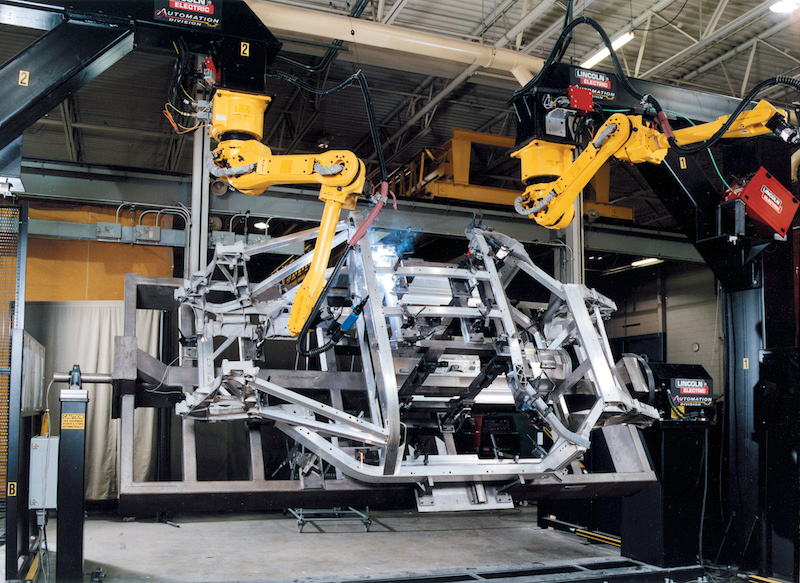

The most crucial aspect in automotive business is to develop light weight element in order to improve the efficiency of the vehicles and minimize the fuel consumption. The automotive sector tends to make use of complex engineering … READ MORE >>>