The Four Types Of SteelAutomobiles require a wide variety of raw components for their production, such as the iron employed for steel, aluminum, glass, the petroleum items utilized to make plastics, rubber, and specific fibers. Jetgal® has been especially developed by ArcelorMittal for cold rolled sophisticated higher strength steel (AHSS) employed in automotive applications such as Fortiform® This pure zinc coating is applied making use of a hydrogen-cost-free coating process known as Jet Vapor Deposition (JVD). Hoffman, 2012 Steel lightweight supplies and design for environmental friendly mobility. Thyssenkrupp Europe.Aarhus.

The introduction of new components into automotive manufacturing has typically been dictated by how rapidly such components can be processed in the production line. Compared with a fleet of conventional steel vehicles, aluminum use saves the equivalent of 108 million barrels of crude oil in energy. Pound for pound, aluminum can absorb twice the crash power of mild steel. Larger crush zones can be developed without having corresponding weight penalties.

Element D: Properties. Portion D covers material properties of all these components that are permitted per Sections I, III, and VIII of the ASME Boiler and Stress Vessel Code. The selection of chassis material varies from manufacturer to manufacturer, it ranges from aluminium alloy to carbon fibers. However, in context of your answer i would say that the preferred material now is IF(Interstial cost-free) grade stainless steel.

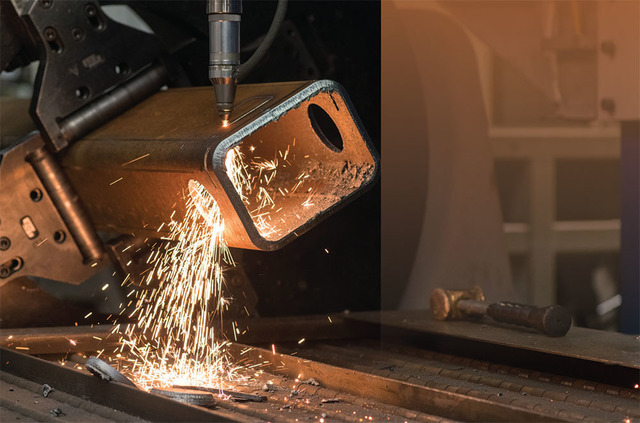

New Steel Grades Drive PMI Programs In Automotive ManufacturingTypes Of Steel Used In Automotive Industry

type of steel used in automobile industryAnnealing is a approach by which the properties of steel are enhanced to meet machinability needs. In order to assess the present shift, it is useful to have a brief appear at the evolution of automotive supplies use. Aluminium was very first utilized in car bodies in the premium segment. Hence, the first mass created automobile with a full aluminium physique was the Audi A8, which produced its debut in 1994. Other luxury brands soon followed suit: BMW, Mercedes-Benz, Porsche, Land Rover, Jaguar.

According to , aluminum-bodied autos are safer than their steel counterparts thanks to greater energy absorption, larger crush zones that fold more predictably and bigger general size. Since aluminum is lighter, it allows automakers to improve dent resistance—they can make body panels thicker although nonetheless lowering weight. And a reduce weight car has much better acceleration, far better braking and greater handling. In addition, lighter autos can haul and tow much more due to the fact the engine isn’t carrying unneeded weight.

However, aeroplanes made from composite supplies price a lot much more to create than planes produced from aluminium. In addition, carbon composite supplies usually never deliver the required level of security. The body and chassis make up over half the weight of the typical vehicle, so material can make a big distinction in weight, stiffness and strength of the car. According to Dr. Hall, the tensile strength of steel is up to 2,000MPa (290,000psi), which is about 4 occasions stronger than the strongest aluminum alloys accessible today.

Cast Iron Sortsfour types of steel rules

Types Of Steel Used In Automotive IndustrySteel is ubiquitous in a vast number of industries, from residential, commercial and industrial building, to shipbuilding and automotive, to manufacturing. There are tradeoffs when it comes to each and every of these supplies, whether that be cost or comfort. Carbon fiber is typically only utilized in vehicles with hefty value tags, but it is a single of the most powerful ways to preserve or enhance strength whilst decreasing cost. Each and every material also presents its personal manufacturing problems. Titanium, for example, is difficult to perform with due to its impressive strength. Structural Glass fiber can turn into a hazard to workers. When it comes to selecting a material to lightweight a automobile with, it typically comes down to the minute information of a design and the manufacturing capabilities of the company.

In 2014 the worldwide automotive sector (excluding China) consumed 2.87 million tonnes of aluminium. By 2020 it really is expected to be consuming four.49 million tonnes of aluminium a year. Key aspects of this growth incorporate both increasing automotive production and wider use of aluminium in contemporary vehicles. Current developments have shown that up to 50% weight saving for the physique in white (BIW) can be accomplished by the substitiution of steel by aluminium. This can outcome in a 20-30% total automobile weight reduction.

Components and an Analysis of the Future.Wonderful Styles in Steel. With AHSS, automobile producers are utilizing significantly less material and saving a lot of mass. The research carried out by WAS have demonstrated in a quantity of projects (most current is ‘Future Steel Car-FSV) that the use of 97 % of the high strength steel (HSS) and AHSS has saved 39 % mass over the benchmark weight.

Adhesiveness Of Cold Rolled Steels For Auto Physique Componentsthe 4 types of steel

what are the 4 types of stainless steelNo matter whether metal is utilised to make tools, build skyscrapers, or lay railways, strength is an crucial consideration when deciding which metal best suits the job. There are a wide variaty of aluminium usage in automotive powertrain, chassis and physique structure. Use of aluminium can potentially reduce the weight of the vehicle physique. Its low density and high distinct energy absorption overall performance and very good particular stregth are its most important properties. Benz was also responsible for the first production auto (1200 units) in 1894 and a new generation of commercialised vehicles was born. Crucially, the method of varnishing wooden bodywork to make it sufficiently resilient was both time-consuming and pricey.

Once more, early adoption of the material comes from Formula One particular where its higher cost is significantly less of a aspect than its properties. Nevertheless, some car companies have started to introduce carbon fibre in their production lines. This tensile strength difference signifies that aluminum parts need to enhance thickness to meet safety standards, even though sophisticated high-strength steel (AHSS) can be created thinner, thereby lowering weight. Granted, these thicker aluminum parts might nonetheless come out lighter than their steel counterparts.

Correct from the very first automobiles till the present, steel has been the preferred alternative for structural components requiring high strength. But, with the want to generate lighter cars becoming driven by the CO2 emission regulations imposed for new auto builds, this is likely to modify. Strength Steel (AHSS) has also been elaborated. Nevertheless, with environmental studies displaying a correlation amongst decrease weight automobiles and reduce CO2 emissions, there is considerable impetus to pursue the lightweighting trend (1).