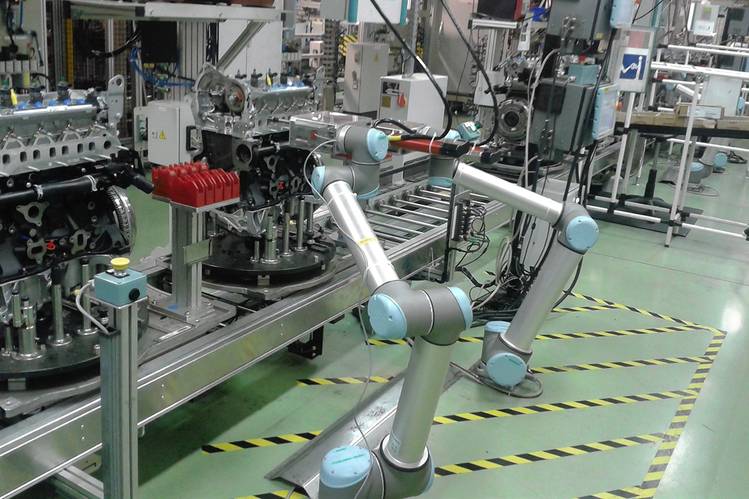

Collaborative robot automotive industryAccording to Universal Robots, if the number of industrial robots doubled, the number of workers would also enhance. Vehicle assembly operations and automotive part producers are some of the most significant users of robots in the automobile manufacturing market. Robots are less difficult to plan and deploy than ever, but each integration project comes with exclusive challenges. That’s why producers interested in adopting automotive robotics ought to operate with an seasoned integration companion for design and style and installation.

Production line, or assembly, robots are best for tasks requiring both speed and accuracy. Furthermore, they are beneficial in environments that demand immaculate cleanliness such as pharmaceuticals or healthcare device assembly. Robots by no means tire, get ill or endure debilitating injuries, creating them a useful investment for companies in a variety of manufacturing verticals.

Flexible automation and robotics can assist producers in meeting the demand by offering energy-efficient solutions which also enhance productivity. Indeed, robot sales to the automotive sector have improved from 19.three thousand in 2009 to 69.4 thousand in 2013. Visiongain expects automation & robotics in automotive manufacturing to attain a worth of $13.66bn in 2014.

Cobots Drive The Automotive Sector Forward application of robots in automobile industry ppt

industrial robots in automotive industryAccording to Universal Robots, if the quantity of industrial robots doubled, the quantity of employees would also improve. AGVs are operator-free of charge transport systems created to move raw material and parts repetitively more than brief-to-medium distances. They use lines, tape or magnet infrastructure to travel from A to B. Sensor cameras are now being added to produce vision-guided cars (VGCs). This evolution uses 3D map technology to navigate autonomously through crowded manufacturing plants.

There are hundreds of various sorts of robots performing a multitude of tasks. These operational functions are commonly categorized employing criteria such as kinds of movement (degrees of motion), application (welding, material handling, etc.), architecture (serial robots and spider robots) and collaboration – a fairly new type of robot that can perform alongside humans without getting caged off.

Karabegović I. Karabegović E. Mahmić M. Husak E. 2015. The application of service robots for logistics in manufacturing processes, Advances in Production Engineering & Management, Vol. ten. No. 4.Maribor, Slovenia, pp:185-194. Robotic welding has been the top robotic application in the automotive sector for a long time, as every car wants a higher number of welds before it is comprehensive. Offered the higher worth of the completed item, productivity from automation is massive.

The Automotive Sectoruse of robots in automotive industry

collaborative robot automotive industryIn the last six years, (2010-2015), according to the IFR (International Federation of Robotics), US market has installed about 135,000 new industrial robots. Due to strict top quality and productivity requirements, new robotics applications are getting identified, e.g. carving of tire tread profiles. Stäubli Robotics brings precision, dynamics, path accuracy and reliability to interior, body and security, powertrain as properly as wheel and tire applications. Presently, a lot of manufacturing industries, especially the automotive sector, have been struggling to lessen production expenses: the price of production materials and parts have considerably improved.

Worldwide there are more than 2 million industrial robots and 2017 saw the largest sales volume in the industry’s history, of 381,000 units. Much more than a third of the total was acquired by China, which also has the largest quantity of robots in service – 470,000. These days,” Johnson adds, new manufacturing strategies automatically integrate robots. The Romanian industry has doubled its robotic density, from 9 to 18 robots per ten,000 workers amongst 2014 and 2017, according to the International Federation of Robotics (IFR).

Applications in which robots excel: installing sensitive sensors, deployment on complicated assembly lines and elements cleaning. Element Transfer: Pouring molten metal in a foundry and transferring a metal stamp from a single press to the subsequent are unpleasant jobs for human workers, but they’re excellent robot tasks. Robots have and will continue to drive efficiencies and price savings in the automotive sector, as more and more processes turn into automated. At the same time, growing flexibility in production will become possible – meeting today’s demands for customisation and the new era of automated vehicles.

Robots Have On The UK Automotive Industry?application of robots in automobile industry ppt

collaborative robot automotive industryAccording to Universal Robots, if the number of industrial robots doubled, the number of staff would also improve. Acieta has effectively installed more than four,400 industrial robots more than the last 34 years in North America. To find out how we can aid you implement robotics in automotive manufacturing, speak to us right now. Audi was one particular of the pioneers of the new technologies, introducing a robot that hands coolant expansion tanks to line workers at its Neckarsulm production facility. Volkswagen has also employed similar helper robots to assist for the duration of vehicle assembly, as have Mercedes-Benz and Opel.

Fanuc will soon be coming out with a robot simulations tool. This will allow manufacturing engineers to look at robots in 3D space, perform out cycle times and other technical matters, and then download to actual robots. In 1969, the Stanford Arm was developed. With six degrees of freedom, it was capable of tasks earlier robots could not perform. Reports on trends in the design and application of robots in the Japanese automotive business.

These collaborative robots are built to perform collectively with other robots, on huge assembly lines. Robots have to collaborate between handling and welding robots to make such assembly lines function properly. The manufacturing method of a auto is time- and expense-intensive. Automotive cobots give you all the positive aspects of sophisticated robotic automation with none of the added costs connected with conventional robotics. Robot arms from Universal Robots have the fastest payback in the industry.